ड्रेसर नट वाल्व

जांच भेजें

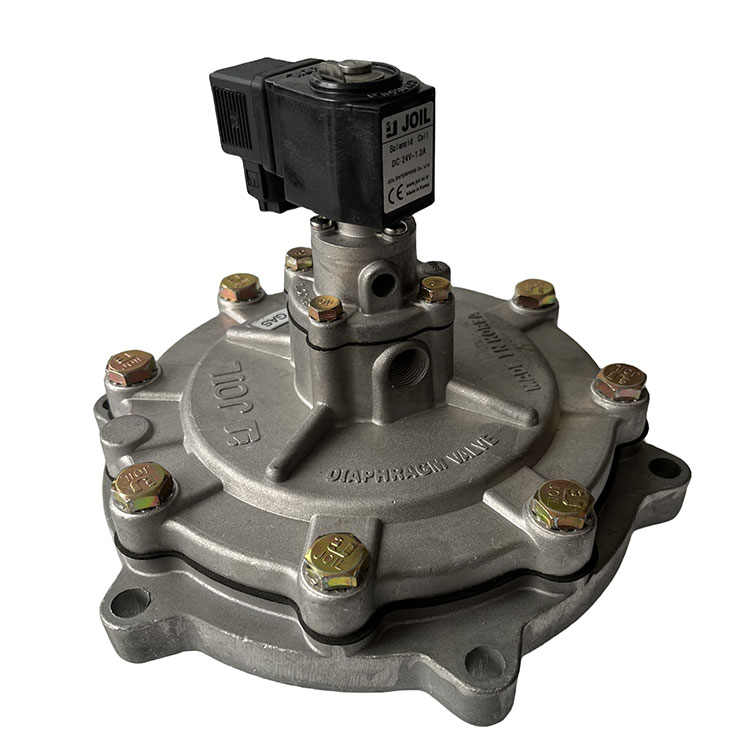

Boost your industrial dust disposal's effectiveness with Qingdao Star Machine's high-end Dresser Nut Valves. Solenoid/air control valves are extensively utilized for cleaning ventilation and dust in industries such as industrial boilers, iron and steel, metallurgy, foundries, chemicals, construction materials, machinery, and rubber manufacturing. The advised duration of 50–500 ms, coupled with a suggested interval of no less than 1 minute between pulses, ensures peak efficiency.

It's crucial to separate components from pressure and energy sources for maintenance purposes. Apply pressure and power again only once the valve is fully assembled. Annual inspections of the diaphragm and pilot are recommended to ensure peak operational efficiency. Depend on our Dresser Nut Valves for robust and reliable industrial filtration systems.

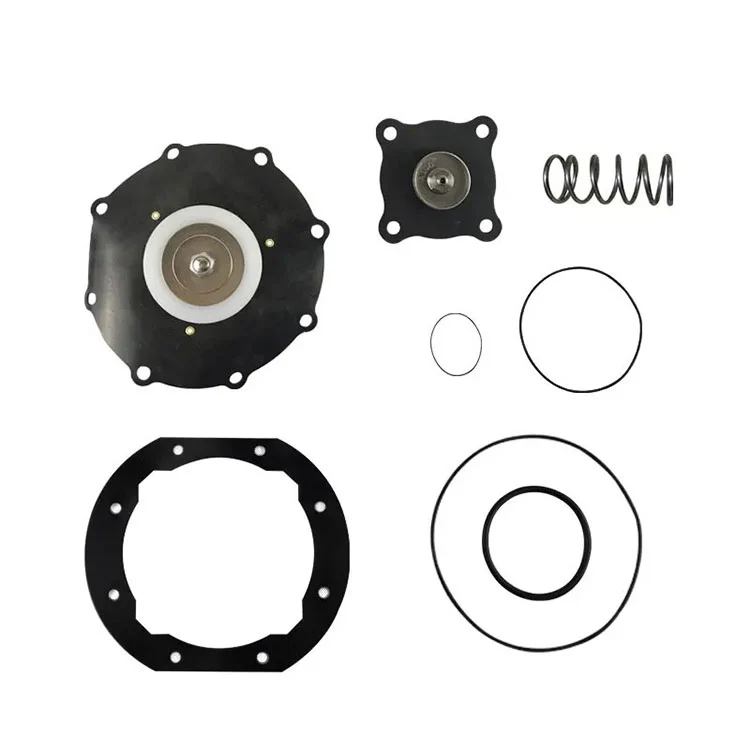

Product Construction

The structure of Dresser Nut Valves is shown below.

| NO | Name | Material instruction | NO | Name | Material instruction |

| 1 | Coil | Good quality wire | 8 | Big spring | 321 stainless steel |

| 2 | Pilot kits | 430FR stainless steel | 9 | Fastener | 302 stainless steel |

| 3 | Small cap | ADC aluminium | 10 | Diaphragm kits | Imported NBR |

| 4 | Middle cap | ADC aluminium | 11 | Valve body | ADC aluminium |

| 5 | Small spring | 321 stainless steel | 12 | Nut | ADC aluminium |

| 6 | Diaphragm kits | Imported NBR | 13 | Seal | 302 stainless steel |

| 7 | Up cap | ADC aluminium | 14 | Seal | Imported NBR |

Product Parameter

| Model | CA20DD | CA25DD | CA45DD | |

| Nominal Size | 20 | 25 | 45 | |

| Port Size | mm | 20 | 25 | 45 |

| in | 3/4 | 1 | 1-1/2 | |

| Number of Diaphragms | 1 | 1 | 2 | |

| Flow | Kv | 12 | 20 | 44 |

| Cv | 14 | 23 | 51 | |

| Pressure(PSI) | 5 to 125 | 5 to 125 | 5 to 125 | |

| Temperature℃/℉ | NBR | -40 to 82/ -40 to 179.6 | -40 to 82/ -40 to 179.6 | -40 to 82/ -40 to 179.6 |

| FKM | -29 to 232/ -20.2 to 449.6 | -29 to 232/ -20.2 to 449.6 | -29 to 232/ -20.2 to 449.6 | |